TUFS

THERMAL

UNDER FLOOR SYSTEM

INTRODUCTION

Thermal insulation of buildings is becoming increasingly

relevant

as energy costs rise and climate change a reality.

Expanded polystyrene (EPS) is one of the most efficient

and cost effective materials

to provide thermal insulation in buildings.

One area that acts as a thermal heat soak is the under

floor area of any building drawing heat generated

inside buildings into the ground.

The TUFS under floor insulating system acts as a easy

to install under floor insulation system as well as

having a number of other functions and benefits.

PRODUCT DESCRIPTION

• TUFS is a 40mm thick, EPS, under floor, thermal

insulating system used as an integral part of ground

floor slab systems between conventional foundation

walls.

• TUFS panels are 1,2 x 1,2 m square and are

joined together by tongue and groove edging and a

propriety expanded polystyrene adhesive.

• TUFS prime function is to insulate ground

floor concrete slabs but it also acts as a moisture

proof barrier replacing the continuous plastic sheeting

normally used for this purpose.

• The TUFS sheets substitute approximately 50%

of the concrete used in conventional concrete floors

and due to the lower concrete volume the steel mesh

size used can also be reduced.

• TUFS can also be used as an EPS thermal insulating

cavity former in external brick walls. In this application

it will also have a dual function of creating an ‘in

wall’ moisture barrier.

PRODUCT

BENEFITS

Ground

floor insulation

EPS is used in a multiplicity of applications for

its thermal insulating properties. TUFS acts as a

thermal barrier to prevent under floor cold penetrating

rooms and keeping heat generated in houses from being

dissipated into the ground.

As a vertical brick wall ‘cavity former’

TUFS will act as an in wall thermal insulation barrier.

Water proof barrier

EPS is impervious to water and with the combination

of the TUFS tongue and groove joining of the sheets

secured by a glue line provides a continuous under

floor moisture barrier. Plastic sheet DPC membranes

are thus no longer necessary.

If used for wall insulation TUFS will also work to

create a vertical moisture barrier.

Concrete reduction

and reduction of potential for surface cracking

The 40mm TUFS sheets replace almost half of the concrete

used in a conventional 85mm ground floor slab reducing

cement usage and the heavy labour required in placing

the concrete.

As the concrete volume is halved the shrinkage stress

of the concrete is reduced and as the EPS spacer blocks

ensure the reinforcing mesh sits just below the floor

surface its function to reduce cracking is

optimised.

Reinforcement

mesh size reduction

As the concrete volume is reduced the mesh size can

be reduced typically from a 193 mesh to a 100 mesh.

This reduces the cost and eases material handling.

Optimisation of

underfloor heating systems

If under floor heating is installed the TUFS system

should be obligatory. TUFS will ensure that heat generated

is not absorbed by the ground and is forced upwards

into the house itself.

Floor Loading

Typically design loadings for floors should be:

|

Domestic |

Non-Domestic |

Intensity

of distributed load (kPa) |

1,5 |

2,5 |

Concentrated

loads(kN |

1,4 |

2,7 |

TUFS flooring can support these loadings without undue

deflection.

Long life

EPS is rot and rodent proof and dimensionally stable

and thus will retain its thermal insulating and moisture

barrier effectiveness for the life of the building.

Cost

The elimination of the need for plastic sheet DPC,

the substitution of concrete with EPS at near cost

equivalence and the reduction of the size of the reinforcing

mesh means that the TUFS composite floor system will

give the advantages of thermal insulation at no extra

cost.

When used as a vertical thermal insulating cavity

TUFS will ass a nominal amount to the building cost

providing significant benefits reducing energy consumption

required for heating and cooling.

PRODUCT SPECIFICATION

EPS sheets:

Expanded polystyrene sheet size: 1,2 x 1,2 m x 40mm

thick

EPS density: 16 gm/lt

Fire retardant additive: YES

Edge configuration: 2 sides 10mm deep x 20mm thick

rectangular tongue

and 2 sides 10mm deep x 20mm high groove.

Thermal conductivity: 0,038 w/mK

EPS spacers:

Expanded polystyrene blocks: 35mm high x 40mm square

with 5mm cross groove on upper surface

Number: 4 per each standard TUFs sheet

Adhesive:

Polyglue SBR expanded polystyrene adhesive packed

in 1 and 5lt tins.

1lt of Polyglue will be sufficient to glue 20-25 TUFS

sheets.

Sales code:

TUFS001 = 1,2m X 1,2m x 40mm TUFS sheets

SYSTEM

APPLICATION

UNDER FLOOR:

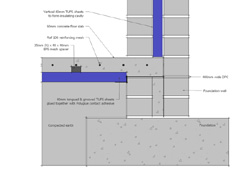

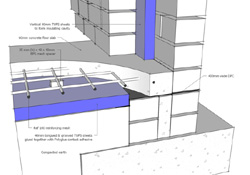

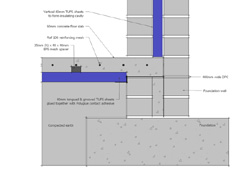

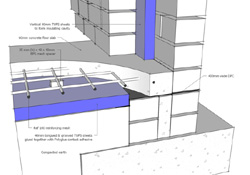

1) Concrete strip foundations and foundation walls

are built as normal

2)

Stepping of external walls to accommodate the floor

slab is done as normal.

3) Compact earth up to the under side level of the

floor slab.

4) Strip plastic DPC is laid on top of the brick course

on which the floor slab will rest.

5) TUFS sheets are laid from the inner edge of the

brickwork over the compacted area starting from a

corner, glueing and locating the tongue and groove

sheets as the area is covered. TUFS sheets are cut

with a handsaw or knife to fit exactly into the walled

area and offcuts kept to use elsewhere and prevent

wastage.

6) The bottom of the TUFS sheets should be about 20mm

below the top surface of the inner brick to allow

a 65mm covering of concrete.

7) 35mm thick 40 x 40mm EPS steel mesh spacer blocks

are fitted to the underside of the steel mesh before

laying this onto the TUFS sheets. This ensures that

the steel mesh is located where it is most needed

to prevent shrinkage cracking of the concrete - just

below the top of the concrete surface. 4 spacer blocks

are used per TUFS sheet.

8) Electrical ducting etc can still be run in the

concrete top section but if larger piping is run in

the floor this can be cut into the EPS sheets.

9) Concrete is then poured to complete the composite

floor construction and surface finished as normal.

IN WALL:

1) Build one skin of brick wall place TUFS sheets

vertically against the bricks and then proceed to

build other brick skin wedging the TUFS sheets in

the centre.

2) Glue the tongue and groove sheets and cut to fit

around windows and doors.

3) Final wall thickness will be 260mm as opposed to

conventional 220mm.

|