PRODUCT

DESCRIPTION

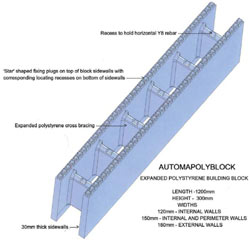

ABPPolyblock is a hollow EPS building block which

acts as a permanent formwork for a reinforced

concrete infill and is used for building houses,

perimeter and retaining walls, infill panels for

steel frame construction, agricultural buildings

and high rise developments.

The block stays in place acting as a thermal insulator

for the building.

The system is finished by using a propriety EPS

plaster - Polyplast

ABPPOLYBLOCK

SIZE |

CODE

|

FUNCTION |

CONCRETE

REQ./M2(m3) |

WALL

WEIGHT

M2 (kg)

|

1200mm

(l) x 300mm (h) x 180mm (w) |

TAWB180 |

External

walls |

0,1 |

240 |

1200mm

(l) x 300mm (h) x 150mm (w) |

TAWB150

|

Perimeter walls |

0,075

|

180 |

1200mm

(l) x 300mm (h) x 120mm (w) |

TAWB120

|

Internal

walls |

0,05

|

120 |

The

EPS block walls are 30mm thick.

ABPPolyblock 'K' is a knock down block where long

distance transport is an issue.

Variblock 'R' is a retaining wall system which

allows the outer EPS walls to be spaced at any

distance apart to suit the concrete width dimensions

required for the retaining walls

SYSTEM APPLICATION

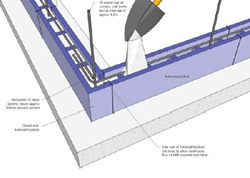

1)

Build foundations, either strip or raft as normal

keeping foundations as level as possible. Foundations

should be stepped by 300mm to suit the height

of the block.

2) Place 1m long starter bars in the foundations

(100mm deep) at corners, wall joins, on either

sides of windows and doors with spacing between1,2

-1,5 m between bars.

3) Place first row of ABPPolyblocks to floor plan

leaving spaces for door frames. Ensure all blocks

are level.

4) Insert first Y8 horizontal rebar continuously

above first block bending around corners by 300mm.

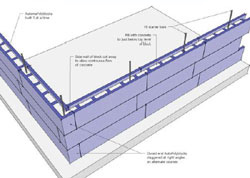

5) Place ABPPolyblocks 3 high and fill with 15MPa

concrete.

6) When concrete set place next 3 rows, fit windows

or formwork for windows and continue to fill with

concrete placing further 1m lengths of rebar vertically,

in line with the starter bars.

7) Use timber or fibre cement formwork above window

openings to hold concrete in place above window

openings.

8) Above windows and doors insert 2 x Y8 rebar

lengths continuously on top of first block above

openings to create ring beam and lintel.

9) Attach hoop iron or wire to the ring beam to

secure roof sub structure and fill with concrete

to wall top.

10) When wall work complete and internal concrete

fully set, plaster with Polyplast plaster solution

to 6mm thickness.

PRODUCT BENEFITS

Permanent thermal

insulation

Polyplast keeps homes warm in winter and cool

in summer saving energy costs involved in heating

and cooling.

Lightweight

Easy to carry and position.

ABPPolyblock walls filled with concrete are about

50% lighter than equivalent sized brick walls.

Quick to build

ABPPolyblock modular blocks are dimensionally

accurate, equivalent in size to 36 bricks and

the patented locating mechanism locks the blocks

together easily and tightly.

No need for

skilled labour

Due to the simplicity of fitting the ABPPolyblocks

and the requirement simply to fill with concrete

skilled bricklayers are not required

Structurally

sound

The structure of the ABPPolyblock system is reinforced

concrete which is 2-3 times stronger than brick.

Speed of construction

Walls can be built up to 5 times as fast as brick

with building rates of 50m2 per day per building

team readily achievable.

Moisture resistant

EPS is water impermeable and the ABPPolyblocks

therefore create a moisture barrier.

Cost competitive

Considering material cost and speed of building

constructing with the ABPPolyblock system is competitive

with building with brick.

Long life

EPS is resistant to rot, bacterial and termite

attack and degradation over time and will retain

its thermal insulating and moisture barrier properties

for the life of the building.

TECHNICAL DETAILS

| Density |

24gm/lt |

| Fire

retardant |

Yes |

| Thermal

conductivity R value |

1,76 |

| Blocks

required/m2 of wall |

2,78 |

| Block

wall thickness |

30mm |

| Block

size configuration |

See

above |

| Concrete

required/m2 of wall |

See

above |

| Wall

weight |

See

above |

| Concrete

strength specification |

15MPa |

| Rebar

specification |

Y8

or Y10 |

View of ABPpolyblock building process