POLYPLAST

EXPANDED

POLYSTYRENE PLASTER SYSTEM

INTRODUCTION

Whilst expanded polystyrene (EPS) in use

has many excellent attributes it often needs

ancillary products such as plasters, coatings

and glues to ensure its successful application

in the building industry.

Polyplast plaster provides protection and impact

resistance to EPS used in applications such

as walls, ceilings and mouldings.

|

|

PRODUCT

DESCRIPTION

Polyplast is a combination of water based acrylics

and short length fibre that when mixed with plaster

sand forms a workable plaster mix that is easy to

apply to EPS, does not shrink or stress crack, has

excellent adhesion, is long lasting and provides the

necessary impact resistance.

There are 3 products in the range:

POLYPLAST - which is most commonly used at

a standard mix ratio of 1 part Polyplast to 10 parts

plaster sand.

POLYPLAST 'W '- which is a diluted version

Polyplast and is used where plaster sands are excessively

dry to facilitate the mixing process. Mix ratio is

1 part Polyplast 'W' to 7 parts plaster sand.

POLYPLAST 'C' - uses a different, cement

compatible, acrylic resin system to allow cement addition

to the mix to speed up the drying. Mix ratio is 1

part Polyplast 'C' to 1 part cement to 10 parts plaster

sand.

Polyplast 'C' is for use in areas of high humidity

or high rainfall where the drying and cure time of

the plaster is likely to be inhibited.

PRODUCT

BENEFITS

Excellent

adhesion to EPS

Polyplast was formulated to provide a product that

has good long term adhesion to EPS. Polyplast provides

a chemical key to the polystyrene surface.

Resistance to cracking

Polyplast does not shrink crack. The elimination of

cement from the mix eliminates any shrinking on drying.

As Polyplast retains some flexibility it resists cracking

associated with building movement.

Easy to mix, easy

to apply

Polyplast can be easily mixed by hand although mechanical

mixing is recommended. The product is easy to apply

by conventional plastering methods and can be straight

edged if required.

Natural appearance

Polyplast takes on the colour of the plaster sand

used giving a 'natural' appearance to the wall or

building if left unpainted.

Water

repellent

Although Polyplast is not water resistant due to the

high sand loading it does have water repellent properties.

If the resin to sand ratio is increased the water

repellancy of the product increases.

Impact resistance. Once full cured Polyplast provides

a tough, hard surface giving excellent impact resistance

to the EPS.

Versatile

Although Polyplast was developed specifically for

application onto EPS it can be used as a decorative

finish onto cement, brick and concrete. Due to the

sand filler loading and inherent flexibility it can

be used as a filler coat to bridge and hide cracks.

Long lasting

The resins used in Polyplast are high quality water

based acrylics which resist UV degradation and weathering.

Cost competitive

Polyplast plaster at 6mm thickness is cost competitive

against normal sand cement plasters at 15-20mm thickness.

FINISHING

OF PLASTERED WALLS

'Natural' appearance

Polyplast walls can be left unpainted with the finished

wall taking on the colour of the plaster sand used.

To maintain a uniform finish colour ensure the plaster

sand comes from the same source and that sufficient

quantities are mixed in one batch to plaster an entire

wall section or panel. Slight colour variances can

be expected from mix to mix even when the sand comes

from the same source.

Sealers

To improve the water resistance of the plaster clear

sealers can be applied to Polyplast. Sealers tend

to darken the plaster slightly.

Two sealer options are available from ABP Building

Products:

1) Dilute Polyplast with 4 parts of water and apply

by brush, roller or spray.

Do not use a higher resin to water ratio as this will

not provide a transparent film and the result will

be a slightly milky finish.

2) Use ABP's Plasterseal which is a clear styrene

acrylate sealer.

Properties of Plasterseal:

| UV

Resistance: |

Excellent |

| Water

Resistance: |

Excellent |

| Colour:

|

Transparent |

| Coverage: |

10-12m2/litre |

Paint

All commonly used exterior and interior paints can

be applied to Polyplast walls.

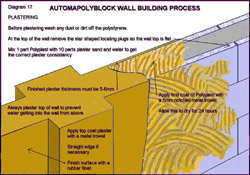

SYSTEM APPLICATION

1.Measure

area to be plastered. At the thickness recommended

(5-6mm) coverage of Polyplast will be 1lt per 2 sq

m of wall.

2.

Mix the Polyplast with plaster sand only at the ratio

1:10. The easiest way to do this is to use a 25lt

plastic bucket - 1 bucket of Polyplast to 10 buckets

of sand.

3.

Mix thoroughly, mixing in a concrete mixer is best

practice to get a uniform mix.

4.

If viscosity of mix is too thin add more sand and

if too thick add more Polyplast.

5.

It is easiest to plaster in two steps:

• Step 1 - using a 5mm notched trowel apply

a 'scratch' coat over the entire surface. This can

be done quickly. Allow to dry overnight

• Step 2 - using a metal float apply a smooth

finishing coat over the notched surface. Final finishing

is best done with a wooden or rubber float using water

sparingly on the surface.

The advantages of plastering this way is that the

notching provides a mechanical key for the finishing

plaster (it is difficult to apply a thick plaster

coat to expanded polystyrene due to the smooth finish)

and the 5mm notches provide a template to control

the final plaster thickness to 5-6mm.

6. As well as finishing with a rubber or wooden float,

finishing can be done with a brush or Tyrolean machine.

7.

Polyplast

can be painted with all types of decorative paints.

8.

In areas with excessively high rainfall or high humidity

it is recommended that a clear sealer is applied to

any unpainted Polyplast surfaces.

9.

Polyplast plaster takes up to 7 days to achieve full

cure and if it rains in this period some softening

of the plaster will be noted. Once dry the plaster

will reharden and the curing process continue.

When plastering in areas with high humidity the

drying and curing of Polyplast may be retarded.

To speed the drying process it is recommended that

an alternative product Polyplast 'C' is used as

this allows some cement to be used in the plaster

mix without any compromise to performance. The recommended

mix ratio is: 1 part Polyplast 'C': 1 part cement:

10 parts plaster sand.

PRODUCT SPECIFICATION

PRODUCT

|

PROPERTY |

MEASUREMENT |

POLYPLAST |

S.G. |

1,04 |

|

Viscosity |

95KU |

|

Solids |

52

+/- 2% |

|

Appearance |

Milky

white liquid |

|

|

|

POLYPLAST'W' |

S.G. |

1 |

|

Vicosity |

61ku |

|

Solids |

39

+/- 2% |

|

Appearance |

Milky

white liquid |

|

|

|

POLYPLAST'C'

|

S.G. |

1 |

|

Visocsity |

60ku |

|

Solids |

47

+/- 2% |

|

Appearance

|

Milky

white liquid |

|