TASS

THERMAL

ACOUSTIC SLAB SYSTEM

INTRODUCTION

With ever increasing building costs, the requirement

for rapid building and greater awareness of energy

conservation as an important aspect of building design,

expanded polystyrene (EPS) is becoming increasingly

used in modern day construction.

The TASS uses the properties of EPS -

thermal and sound insulation, lightweight,

accuracy in moulding and cost competitiveness as the

cornerstone of a patented

multi storey floor slab system.

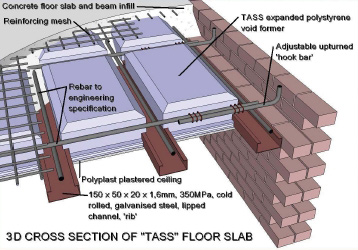

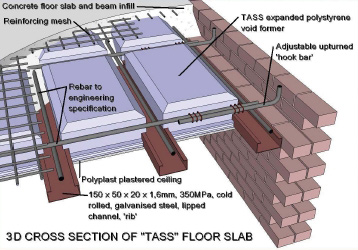

PRODUCT DESCRIPTION

TASS is a combination of a moulded EPS block and cold

rolled steel channel to form a 'rib and block'/coffer

slab system for multi storey buildings.

The system comprises a priority high strength galvanised

steel rib which supports the high density TASS EPS

void formers.

The system is completed by the placement of reinforcing

bars between the TASS blocks in both directions, reinforcing

mesh above the blocks and concrete to fill the channels,

encapsulate the rebar and mesh to form the structure

of the floor slab.

The beams which are created by the concrete infill

and rebar in the gaps between the TASS blocks creates

a monolithic structure.

The TASS void formers are left in place and act both

as a thermal and sound insulator.

SYSTEM

APPLICATION

1)

The floor slab is designed taking into account the

span and load bearing requirements combining the variables

of rebar size and configuration, concrete beam depth

- which can be controlled by the TASS block depth,

and the horizontal floor slab and reinforcing mesh.

2) Support wall structures are built as normal.

3) Steel ribs are placed uni-directionally onto the

supporting walls. These are propped at 1,6 metre intervals

to support the wet concrete and construction loading.

4) Steel reinforcing is fitted between the TASS blocks

in both directions.

5) Steel reinforcing mesh is placed above the blocks

on EPS spacers to position the mesh near the surface

of the concrete slab.

6) If needed, formwork is placed around the perimeter

of the floor area and service ducts to confine the

concrete pour.

7) Concrete is poured to complete the slab.

8) Ceilings can be either suspended or plastered with

Polyplast, propriety EPS plaster system, available

from ABP Building Products.

TASS can be used in the following application areas:

- double storey residential

- multi storey commercial buildings

- hotels

- flats, duplexes and apartment buildings

- shopping centres

- suspended ground floor slabs

- renovations

PRODUCT

BENEFITS

Lightweight

All the components of TASS are lightweight and can

easily be installed without cranes, lifting equipment

or excessive labour.

TASS is approximately 35% lighter than competitive

concrete rib and block systems. This equates to a

saving of about 150kg/m2.

Quick and easy to

install

As the TASS components are made to close dimensional

tolerances (EPS blocks are moulded in closed moulds

and the steel channels roll formed) and lightweight

they can be quickly and easily positioned.

The TASS blocks can readily be cut with a handsaw

when full blocks do not fit and complex shapes have

to be covered.

Electrical and other services can also be cut into

the EPS and run through the blocks themselves.

Fully load bearing

During the construction phase the TASS blocks can

support workmen and equipment allowing full access

to the working area without fear of breakages or damage.

Similarly the system will support the concrete pour

provided the channels are propped at the recommended

intervals.

Thermal and sound

insulation

EPS is used extensively as a thermal insulating material

and performs this function in the slab moderating

building temperatures and reducing energy costs associated

with heating and cooling. EPS also acts as a sound

barrier and in combination with the concrete slab

mutes all sound waves that could potentially be transmitted

through loor slabs.

Fire

performance

A fire retardant grade of EPS is used to manufacture

the TASS slabs and as a result they do not add to

any existing fire hazard and will not contribute to

the development phase of a fire and will not propagate

flame.

Long life

EPS is rot, rodent and termite proof and is dimensionally

stable and will thus retain its thermal and sound

insulating properties for the life of the building.

Cost competitive

TASS is cost competitive when comparing material cost

only vs. traditional concrete systems but becomes

increasingly competitive when including the cost of

labour, equipment requirements and time.

Fewer props are needed per mtr sq for TASS when compared

to concrete systems.

Shorter supply lead

times

The concrete components of traditional 'rib and block'

systems all need lengthy cure periods after manufacture

to reach full strength often increasing supply lead

times.

The TASS EPS blocks are moulded in seconds and the

ribs cold rolled and cut to size immediately.

These alternative manufacturing methods means that

system supply lead times can be significantly reduced.

Versatility

The TASS system can span in two directions which makes

complex designs easier to configure.

Both the TASS blocks and the steel channels can be

readily cut (and welded) on site to accommodate odd

shapes and openings.

Steel formwork edges to limit the concrete can be

formed from various sizes of channel.

Skylights are easy to install by leaving out TASS

blocks and creating edge formers from cold rolled

steel sections.

PRODUCT

SPECIFICATION

System

design:

Design TASS floor slabs as per procedure laid down

in SANS10100 section 4,5 design code.

The design program used to analyse the system is commercially

available from Prokon.

TASS block dimensions:

| Sales

code |

Block

height |

Width |

Length |

Overall

slab depth |

Span |

| TASS

125 |

125mm |

410mm |

800mm

|

180mm |

5,0m |

| TASS

195 |

195mm |

410mm |

800mm

|

255mm |

6,5m |

| TASS

280 |

280mm

|

410mm |

800mm

|

340mm |

8,5m |

| TASS

365 |

365mm

|

410mm |

800mm

|

425mm |

10,5m |

EPS Density: 20gm/lt

Fire retardant: Yes

Thermal conductity: 0,038w/mK

Channels: 150 x 60 x 20 x 1.4mm 350 MPa min. yield

pre-galvanized cold rolled steel.

EPS Spacers: 35 x 40 x 40 mm high density expanded

polystyrene.

Plaster: Polyplast resin solution mixed 1:10 with

plaster sand.

For

additional information on TASS please download the

resources below.

|